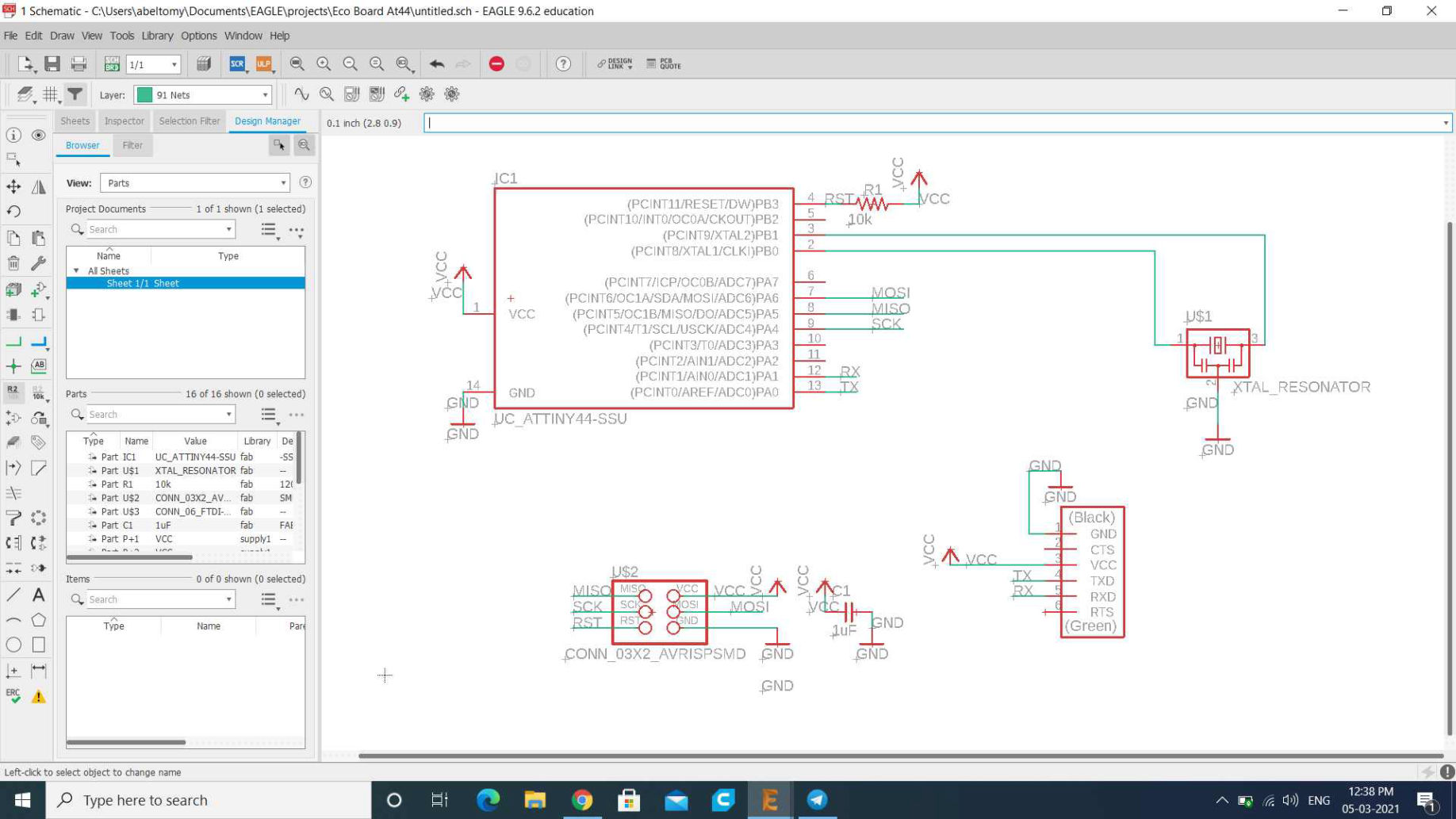

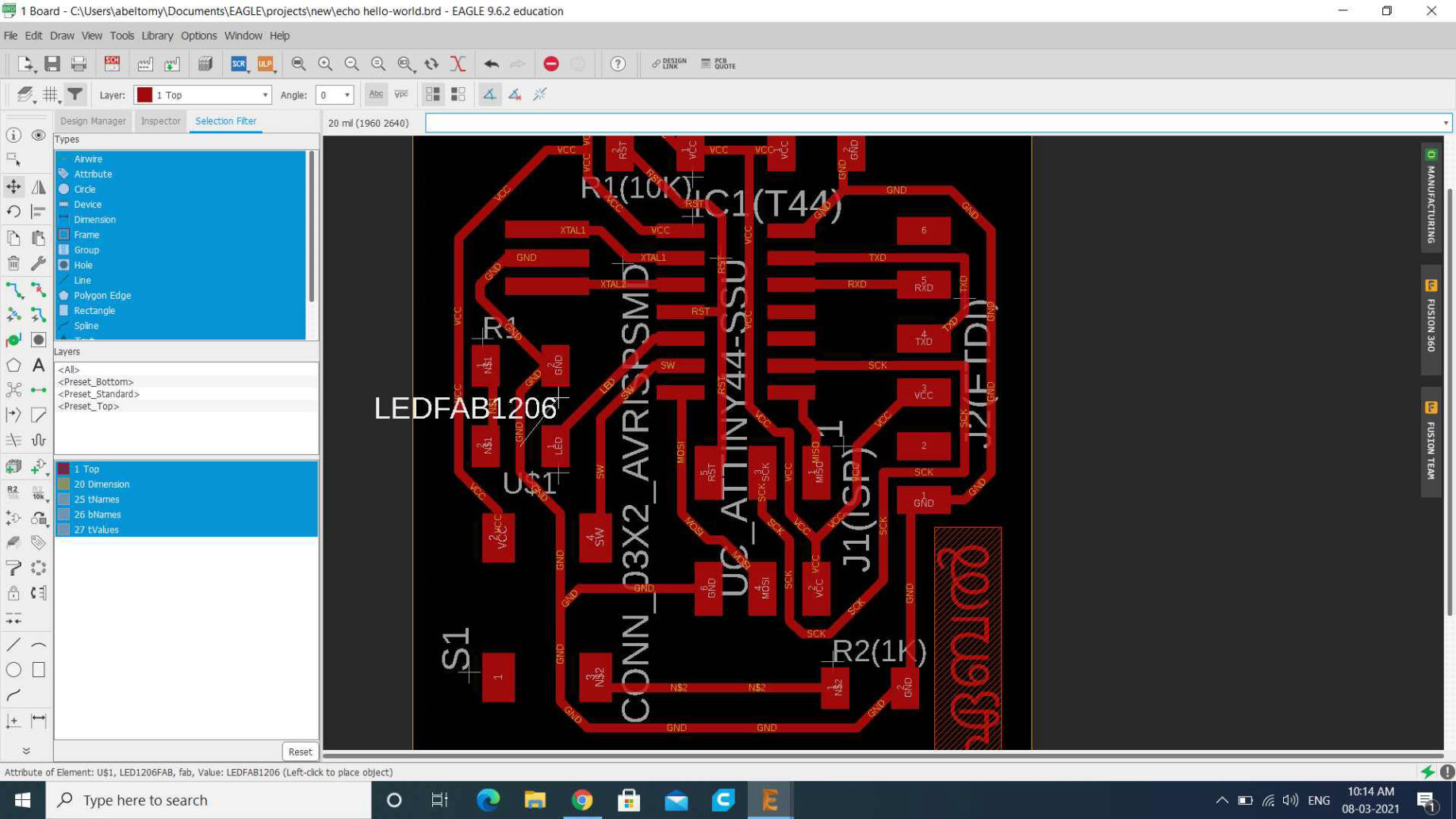

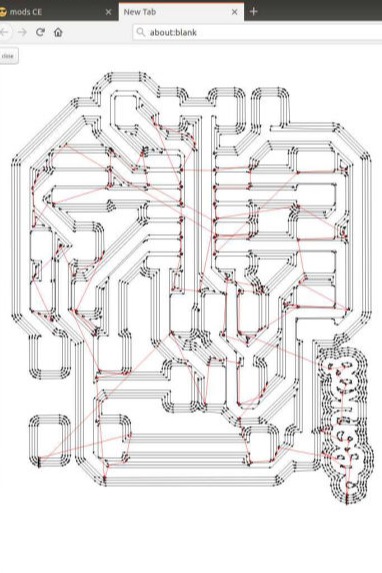

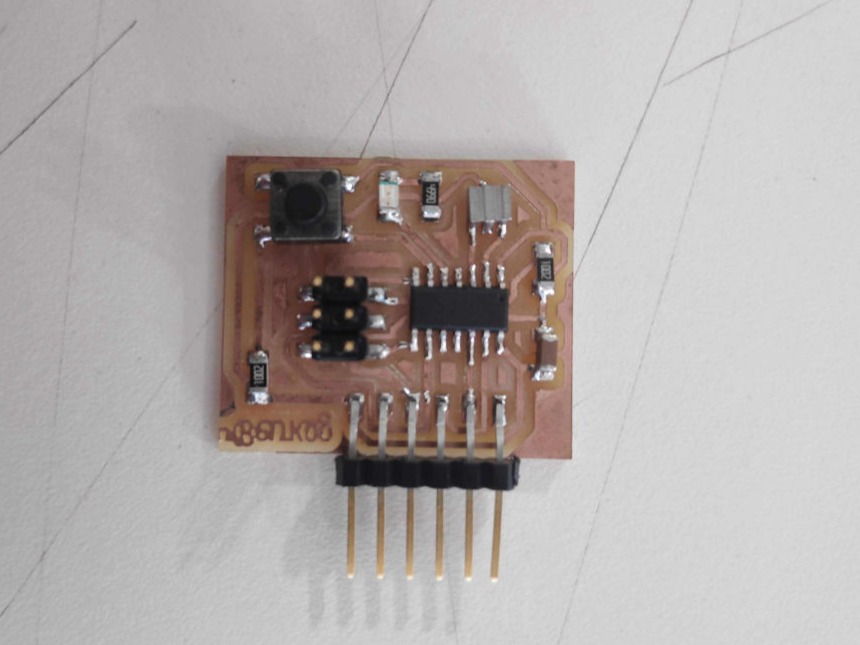

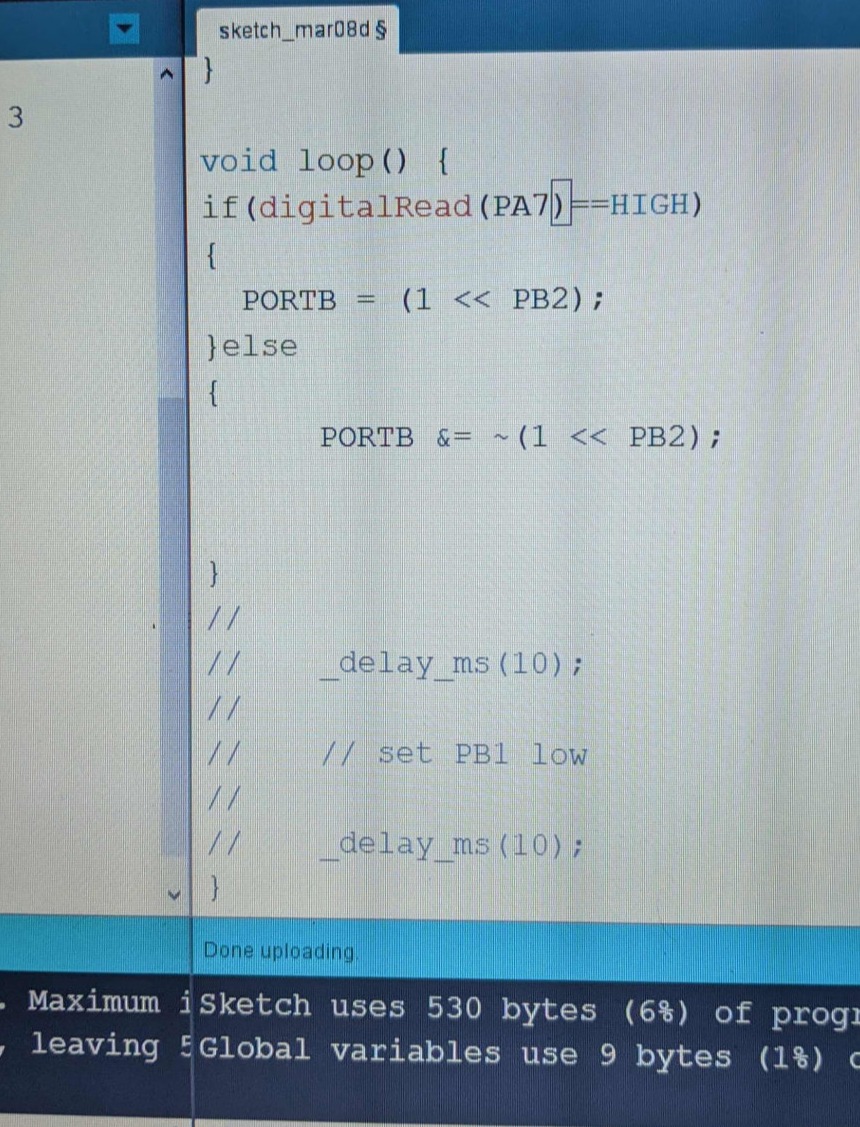

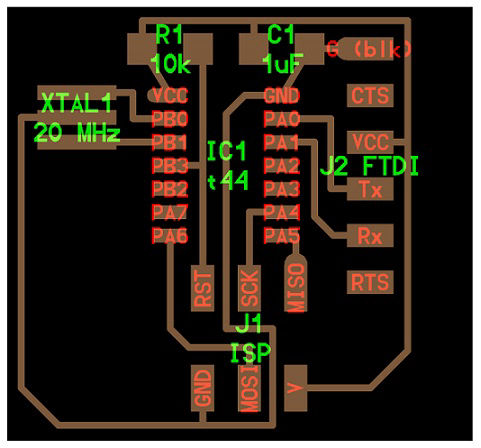

The Assignment was to add a LED and a switch at lest to the circuit.First i drew the basic Echo-board and next i additionally added an LED and Push Button, on the PCB

COMPONENTS

ATtiny44 x 1 - This is a programmable micro controller chip that controls all the parts on the board and is programmed from the computer. Let us say this is the brain of our Board.

XTAL 20HZ x 1 - This Resonance crystal acts as an external clock for the circuit. It needs the input traces to be connected to two pins on the board and the ground trace to the GND circuit.

Resistor 10K x 2

Resistor 99ohm x 1

Capacitor 10uf x 1 - this is a device used to store electric charge, consisting of one or more pairs of conductors separated by an insulator. This will help filter devices to remove voltage or signal spikes in our circuit.

Push button x 1

ISP header x 1 - the 2x3 pin header that connects the FabISP to our newly created chip(ISP - In System Programmer, I have alreay made a FabISP (In System Programmer) board, as part of completing an earlier week’s assignment)

FTDI header x1 -the 1x6 pin header that connects to the special FTDI USB cable (FTDI is Future Technology Devices International - The company that makes a special usb cable - and drivers that let us write to the 6 pin output like a standard serial port.)This will connect the circuit to the computer to both read the program and power the board. It’s VCC and GND pins need to be connected to the respective VCC and GND circuits on the board, and it’s Tx and Rx pins connect to the two free pins on the microcontroller.